Acting as both Principal Designer and Principal Contractor, we initially built a retaining wall to allow the extension of the yard. This also allowed for a new attenuation system. The larger yard gave space for the build of a new portal framed 1,920 sq m, 10m to eaves building, to house manufacturing space, offices, a canteen, and training rooms, plus a new car parking area. Crane rails were fitted inside the building for 2 x 20-tonne and 1 x 50-tonne cranes.

The roof of what became the central building needed replacing. We scaffolded around the building and stripped and replaced the asbestos roof with composite panels, working in phases to minimize disruption to Byworth’s operations. New gutters and downspouts were fitted.

The project required extensive liaisons with Network Rail due to its proximity to the railway line.

Architect: Bowman Riley

This project involved over-roofing a production and office building for packaging manufacturer Solidus Solutions. The 8,700 sq m roof on the triple-span building had previously been over-sprayed with foam but was now leaking. Our works added additional insulation with new plastisol coated steel cladding, discharging water into new galvanized guttering.

The project also involved the replacement of 273m of ridge roof lights.

All completed with the building remaining fully operational for the client during the works.

This dilapidated North light roof had loose slates, fragile discoloured roof lights, and cast iron gutters, all of which were leaking. Further issues included no insulation, little or no ventilation in the working areas, and poor maintenance access to the roof.

We stripped off the existing slates and glazing, and installed a new polycarbonate glazing system, insulation, and plastisol coated steel cladding, together with a new access walkway. We re-lined the existing cast iron gutters and installed a new air conditioning and ventilation system.

The refurbishment of the 26 pitches of roof, covering 11,534 sq m (124,000 sq ft) of manufacturing floor space was completed in phases to minimize disruption to Silentnight’s 24-hour production.

The finished result is a much more comfortable working environment throughout the seasons, bright and clean, fully utilizing natural light and much-improved insulation and ventilation qualities.

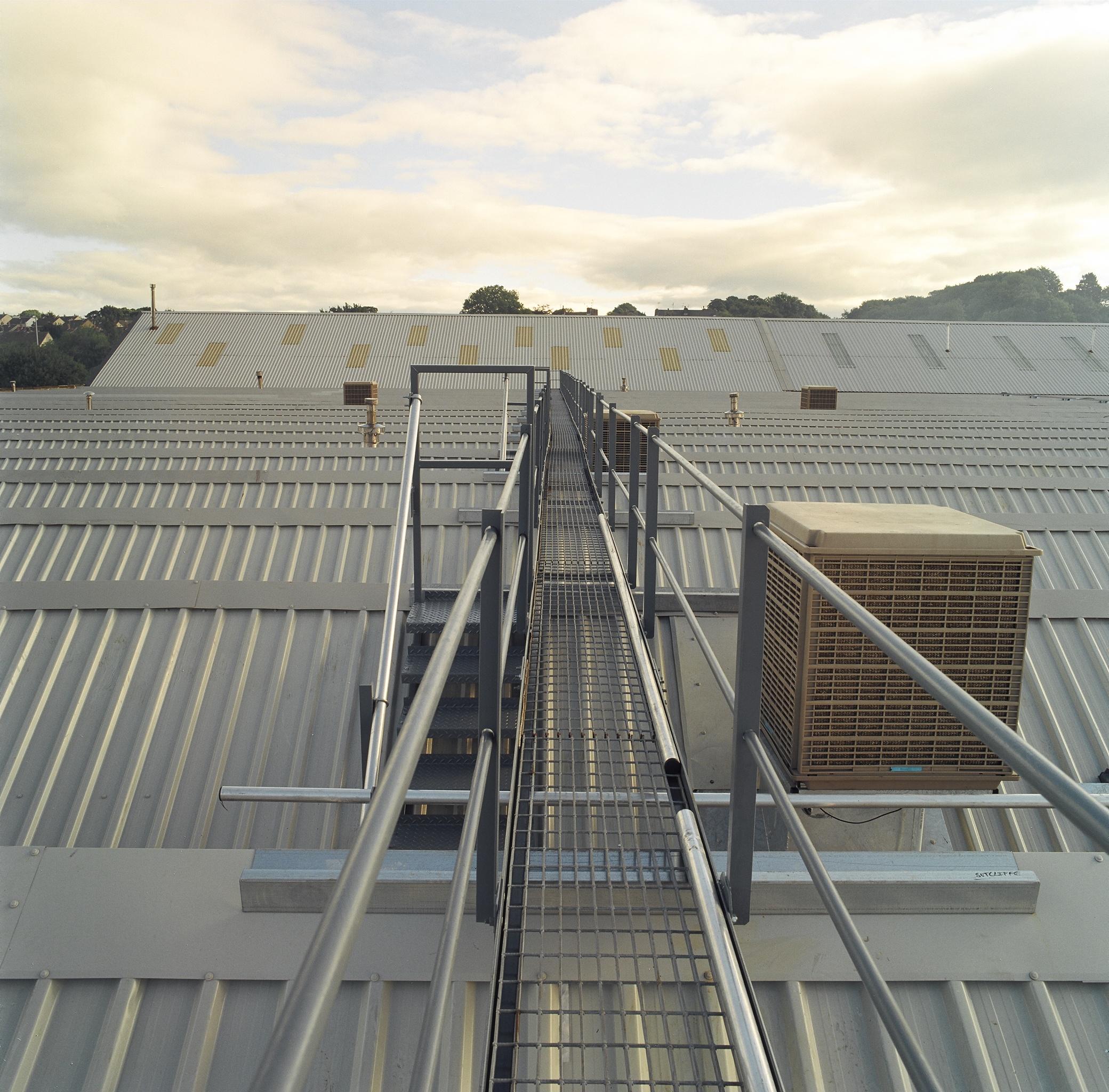

This manufacturing building had blocked guttering and a fragile roof that made it impossible to access for cleaning and maintenance.

We designed, fabricated, and installed a lightweight walkway system over the existing roof to enable easy and safe access. This was installed without ever treading onto the existing fragile roof.

After enduring a number of repairs over the years, the original building’s exterior was an unsightly mix of different coloured brickwork and patches of render. Having constructed a new building for the client on the same site, we were asked to over-clad this double-span building to match the new one. Plastisol coated cladding was used to give this building a fresh new look.